COMPARISON OF HANDMADE AND FACTORY-MADE BLADES

COMPARISON OF HANDMADE AND FACTORY-MADE BLADES

Japan is widely known for producing the finest blades because of its long history of bladesmithing. Japanese bladesmithing started with the production of the oldest steel swords, the Katana, around the 4th century. However, it is believed that the swordsmithing technology used originated in Ancient China and was transferred to Japan through Korea. Japanese bladesmithing boomed by the 16th century, and large-scale production of swords emerged. Bladesmithing then declined with improvements in steel production during the Industrial Revolution. Machine tools that can create blades from flat bars of steel became more readily available at this time.

At present, there are only a few bladesmiths or swordsmiths in Japan; this means the blades are costly and inaccessible to people worldwide who are fond of handmade blades. Katanamart is a European-based company selling superior Japanese swords all over the world. We also have a storehouse in the UK, allowing our English customers to purchase our products without customs fees. We use traditional forging methods to produce a wide variety of professional Samurai Swords including Katana and Iaito. We prioritize the satisfaction of customers with the highest quality hand-forged products at low prices. We also have a wide selection of garments for martial arts and wooden weapons.

Katanamart’s Handmade Iaito Sword

Handmade Blades

Katanamart works with experienced martial arts instructors to ensure the quality of blades produced using the traditional forging method. Here’s how Katanamart produces its excellent quality swords.

Iron Sand and Charcoal Smelting

In a large clay furnace known as Tatara, Tamahagane (steel jewel) is produced by smelting iron sand and charcoal. This step lasts for three consecutive days and is supervised by Tatara masters. The Tatara masters ensure the correct operating temperature and feed the iron sand and charcoal whenever needed.

Steel Sorting

After the three-day smelting, the Tatara masters remove the steel from the furnace and sort it according to carbon content. The steel produced is a combination of high-carbon steel and low-carbon steel. A proper combination of high-carbon steel and low-carbon steel results in a sharp-edged and durable blade.

Steel Purification

The steel from sorting undergoes purification by repeated heating, hammering, and folding. In this step, any remaining impurities are removed, and the right mix of iron and carbon is achieved.

Blade Forging

Once the steel is free of impurities, the high-carbon steel and the low-carbon steel are heated then forged together by hammering. The high-carbon steel is formed into a U-shape where the low-carbon steel fits in, forming a blade with a sharp edge and a durable core.

Blade Coating

During coating, a mixture of clay and charcoal powder is applied to the blade formed by forging. It serves as protection to the blade and is responsible for the blade’s curvy design referred to as Hamon. After the application of the coating material, the blade is heated to just below 815ºC. This is the highest temperature at which cracking will not occur.

Blade Curving

Katanamart’s Handmade Katana Sword

The wavy design of a sword is achieved by quenching the hot blade into the water. The high-carbon steel and low-carbon steel contract due to the temperature difference of the blade and the water, causing the sword to bend.

Blade Polishing

To fully hone the edge of the sword, the blade is polished using grinding and polishing stones several times. This step could last for months.

Assembly

A Hilt

The polished blade is then mounted at the hilt and fitted with a wooden scabbard.

Factory-made Blades

To produce large quantities of blades in a shorter time, several machines are used to speed up the production. While some factory-made blades are forged by machines, some are made with pre-laminated sheets further processed by advanced machinery using CNC.

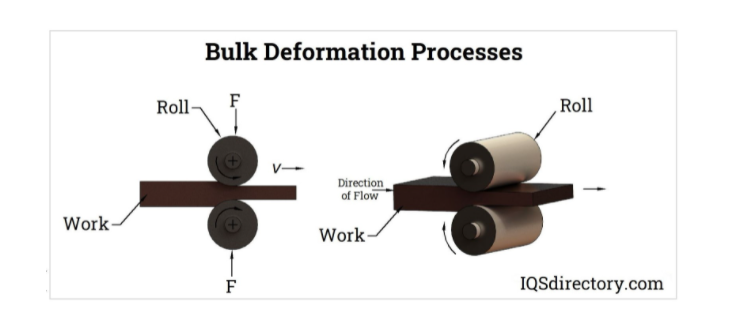

Roller Forging and Cutting Machine

Metal Sheet Deformation During Roll Forging

Instead of having a bladesmith hammer the steel, roller forging machines are used to form large quantities of blades. In roll forging or roll forming, the steel passes through a pair of rotating rollers to reduce the cross-sectional area of the steel. During operation, the two cylindrical or semi-cylindrical horizontal rollers impart a high amount of compressive force that flattens and lengthens the steel. This also gives the forged steel superior mechanical properties. After this, the thin sheet of steel is cut out in the desired shape and dimension. Polishing, assembly, and other finishing steps are carried out manually.

CNC Machining

With a more advanced blade production process, several pieces of machinery utilizing CNC are employed. Starting with a high-quality steel sheet, a laser beam cuts the desired shape of the blade. The laser-cut blade is heated in an electric furnace and cooled twice to improve the hardness and durability. After hardening, the blade is polished using a surface grinding process. The polished blade is attached to the hilt using a machine designed for the assembly process.

While factory-made blades are produced in larger quantities and at a faster rate, their quality does not match that of handmade blades. Handmade blades are constructed, designed, and finished with an exactness absent in factory-made blades. Factory workers do not spend an ample amount of time on each blade as their primary goal is to reach the target production output.

To learn more about our handmade swords, visit our website. For any inquiries, feel free to contact us.